Tile Installation Masters Mississauga

Select professional Mississauga tile experts who thoroughly assess substrates (including flatness, deflection, moisture per ANSI/TCNA), determine suitable primers, membranes (A118.10/A118.12), and mortars, and adhere to EJ171 movement joints. Look forward to laser-layout grids, calibrated rectified tile, correct trowel notch and ≥95% coverage, recorded lippage within TCNA tolerances, and waterproofing photos. They will match materials to purpose (porcelain with DCOF ≥0.42, PEI 4-5), deliver warranties tied to manufacturer systems, and ensure clean, safe installation areas-then, discover how to verify performance with genuine project documentation.

Essential Points

- Qualified contractors adhere to TCNA/ANSI standards, ensuring proper substrate preparation, humidity testing, and movement accommodation joints to avoid system problems.

- Our local project gallery with comparison photos highlights precise grout alignment, expert lippage control, professional waterproofing, and laser-accurate layouts across multiple Mississauga locations.

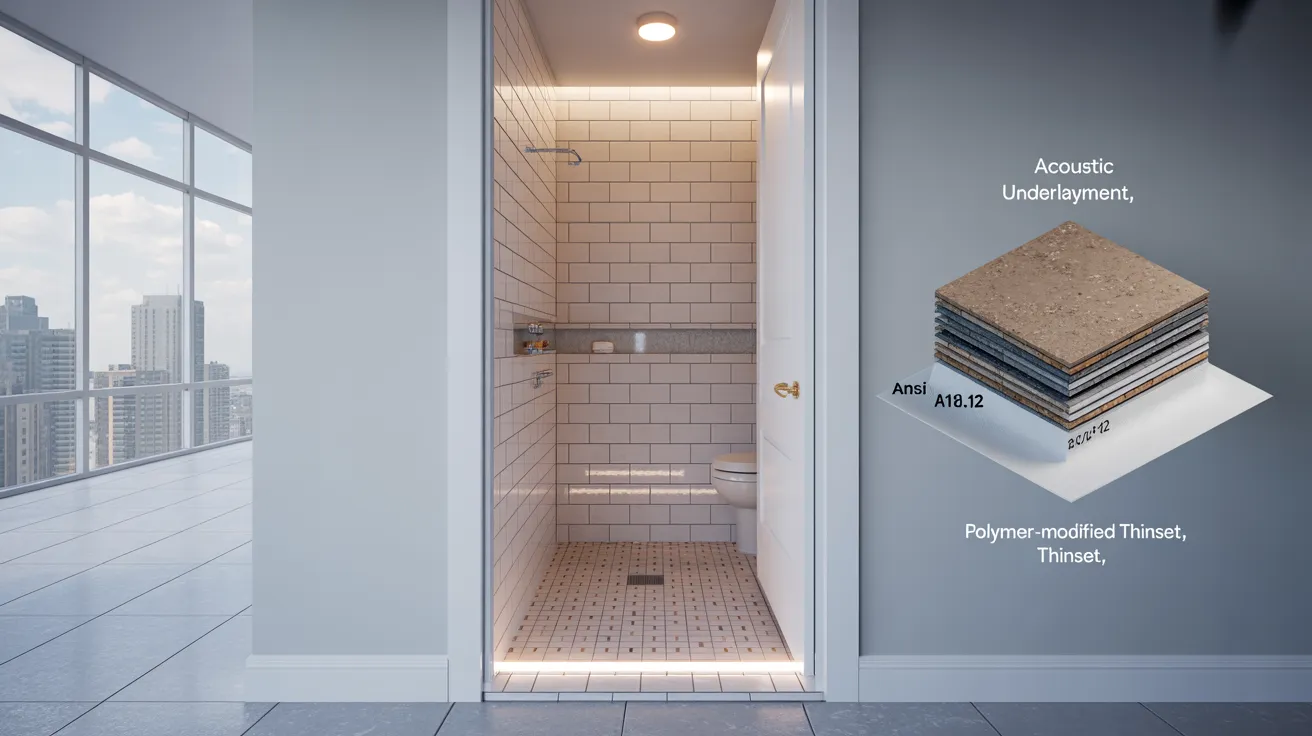

- Material specifications for every space: porcelain having DCOF ≥ 0.42, PEI 4-5 in kitchens, epoxy grout in wet zones, and sound-dampening underlayments as needed.

- Detailed documentation of systems includes mortars, primers, membranes (A118.10/A118.12), trowel requirements, including coverage rates and curing schedules connected to warranty specifications.

- Clean and secure workspaces: we utilize dust management solutions, complete surface coverage, clear timeline planning, and courteous interaction to ensure minimal disruption during installation work.

Why Expert Tile Installation Is Essential

Even though DIY resources make tiling seem basic, expert installation guarantees your tile installation follows professional guidelines and performs as intended. You receive thorough surface analysis, flatness adjustments, and moisture testing that prevents bond failures. Industry experts pick the suitable primers, membranes, and mortars, then ensure correct trowel notch, coverage, and control joint installation based on TCNA and ANSI guidelines. They implement laser grids to position grout joints and optimize sightlines, protecting design beauty.

You'll get specified curing periods, expansion allowances, and deflection standards, which help prevent surface issues and uneven edges. Professional installers confirm slope requirements, edge clearances, and joint connections for code-compliant, secure results. They also provide warranty coverage for designated materials and manufacturing guidelines, safeguarding your project. In essence, accurate techniques, verified methods, and accountable workmanship deliver strong, easy-to-maintain, and visually balanced results.

Finding the Right Tile for Every Space

You'll need to match tile requirements to room demands using defined performance standards. In bathroom spaces, choose moisture-proof products with reduced water absorption (not exceeding 0.5% porosity), slip resistance rated at least R10 or DCOF of 0.42 or greater; for kitchens, focus on wear-resistant porcelain (PEI rating 4-5) and stain-proof finishes. In bedroom spaces, select comfortable, sound-dampening assemblies such as porcelain with cork backing or luxury vinyl tile options with acoustic underlayment satisfying acoustic rating requirements.

Bathroom Moisture Protection Guide

Because of bathrooms face continuous humidity and direct water contact, it's crucial to opt for tiles with minimal water absorption, verified slip resistance, and established chemical durability. Select porcelain tiles with water absorption rates of ≤0.5% (according to) ISO 10545-3 and conforming to COF/DCOF standards (ANSI A326.3). When it comes to shower floors, utilize small-format mosaics for grout traction and proper slope conformity; for walls, install rectified porcelain or glazed ceramic tiles with vitreous construction.

Install waterproof membranes as per ANSI A118.10 under tile in wet areas, and apply epoxy grout (ANSI A118.3) for improved stain and moisture resistance. Handle junctions with sealed movement joints (TCNA EJ171). Ensure correctly sloped shower pans (¼ in. per foot) and completely adhered, polymer-modified thinset (ANSI A118.4/15). Optimize moisture control with ventilated showerheads and a properly rated exhaust fan to achieve ACH targets.

Durable Kitchen Surfaces

Choose tiles that can withstand high traffic, dropped cookware, oils, and thermal shock. In a busy kitchen, specify porcelain tile rated PEI 4-5 and ANSI A137.1 compliant. Choose through-body porcelain for concealing damage and ≥0.42 DCOF for slip resistance. For countertops or islands near stone countertops, verify heat resistance and thermal expansion compatibility; select tiles with low water absorption (≤0.5%) and high Mohs hardness. Install rectified edges for narrow joints and epoxy grout for durability against stains and acids. For backsplashes, opt for glazed porcelain with Class A stain ratings. Check R11/R12 textures in prep zones, and install uncoupling membranes over plywood or concrete to reduce cracking. Treat natural stone only if used as accents, and select color-body trims for clean terminations.

Cozy, Quiet Bedroom Tiles

Even though bedrooms demand softness and hush, tile can provide both when you select the right installation. Select porcelain or engineered stone with a non-glossy finish (matte ≤10 GU) to minimize reflections and distraction. Opt for formats with rectified edges to minimize joints (2-3 mm) and decrease grout lines. For soft acoustic performance, lay over a high-density underlayment (≥20 dB ΔLw) and decoupling membrane meeting ANSI A118.12 to minimize impact sound and separate movement.

Pick slip-resistant tiles for bare feet: DCOF ≥0.42 (wet) meets requirements. Install warm-tone materials that are textured for thermal and tactile comfort. Select low-emission mortars and grouts conforming to ANSI A118 standards. Finish with adaptable, color-coordinated grout and perimeter movement joints per EJ171 to avoid creaking and maintain a silent envelope.

Preparing Surfaces and Moisture Management

Before laying a single tile, confirm the subfloor adheres to flatness, moisture, and soundness criteria as outlined in ANSI A108 and TCNA guidelines. Verify deflection, verifying L/360 for ceramic and L/720 for stone. Complete surface leveling to attain the necessary plane: no more than 1/8 inch in 10 feet for large-format tile, as specified by TCNA. Abrade contaminants; remove any hollow or weak areas; repair with polymer-modified compounds suitable for use with your setting material.

Assess vapor emission and relative humidity according to ASTM F2170 or F1869. If readings exceed manufacturer limits, implement moisture barriers or vapor-retarding systems as recommended. For wet locations, use ANSI A118.10 waterproofing; for crack mitigation, utilize ANSI A118.12 isolation membranes. Maintain movement joints as specified in TCNA EJ171. Install compatible primers, mortars, and sealants across the installation.

Precision Layout, Cuts, and Alignment

Set up reference lines and control points to ensure layout accuracy, then dry-fit to confirm module, joint width, and pattern repeat. Mark perpendicular chalk lines, check squareness with 3-4-5 triangulation or laser guides, and align the field to balance perimeter cuts. Utilize calibrated edge spacers to maintain uniform joints and comply with ANSI A108 tolerances. Scribe critical edges, undercuts, and shifts before spreading adhesive. Execute cuts with a snap cutter for ceramics, a wet saw with diamond blade for porcelain and stone, and a hole saw for penetrations; smooth edges with a diamond hand pad.

Ensure lippage according to ISO 13007 standards by monitoring surface levelness and adhesive application. Set from main sightlines, apply mortar to tile backs when needed, and maintain design continuity between doorways and accent surfaces.

Understanding Grout: Selection, Sealing, and Durability

Although tile determines the surface look, grout significantly impacts performance, hygiene, and longevity, so it's important to coordinate grout type based on usage intensity, joint size, and substrate flexibility according to ANSI A108/A118 and TCNA EJ171. Opt for sanded grout for joints 1/8 inch or wider, unsanded for glass or narrow joints, and high-performance cementitious with polymer for standard commercial applications. For areas exposed to water, professional food preparation areas, and stain-prone locations, specify epoxy grout for its low porosity, chemical resistance, and color stability. Be sure to follow movement joints as detailed in EJ171 to avoid fractures.

Following the curing process, apply a penetrating sealer to cementitious grout for protection against liquid penetration; epoxy grout should not be sealed. Verify moisture vapor emission to protect against efflorescence. Maintain with pH-neutral cleaners; only use acids when recommended. Conduct annual checks, reapply sealer to heavily used sections, and immediately repair damaged joints to extend service life.

Straightforward Pricing and Project Timeframes

As project requirements extend from backsplash refreshes to complete mortar-bed reconstructions, we provide itemized pricing based on specific project parameters, material classifications, and TCNA/ANSI installation specifications, coupling it with a detailed project timeline and sequential timeline. You receive detailed quotations with inclusions, limitations, unit pricing, and material allowances clearly outlined. We organize project phases-removal, surface prep, waterproofing, installation, grouting, curing, and final inspection-into phased scheduling, indicating schedule float, dependencies, and inspection hold points.

We arrange work phases to meet manufacturer cure times and TCNA movement-joint requirements, preventing stress-related failures. Lead times for tile, membranes, and trim are listed, with alternative solutions for alternatives. You'll see initial timeframes, completion checkpoints, and adjustment indicators. If scope shifts, we openly revise schedules and costs, prior to continuation.

Respectful Service and Spotless Worksites

We demonstrate our commitment to schedule and cost certainty through our daily site management practices: we maintain OSHA-compliant housekeeping, employ HEPA-filtered dust extraction at source, and partition work zones with zipper barriers and negative air when required. We shield adjacent finishes with Ram Board, poly sheeting, and edge guards, and we stage materials to maximize workplace organization and movement. Regular sweep-and-vacuum routines clear debris; cords and hoses are managed with cable trays to prevent trip hazards.

We communicate clearly about start and end times, utility requirements, and entry protocols, maintaining professional communication throughout the process. Our crews maintain safety standards using proper protective equipment, properly identifying moisture zones, and posting caution notices following WHMIS and site requirements. We properly contain all waste, ensure proper sealing, and maintain consistent disposal, ensuring your space remains secure and operational.

Local Work Examples and Client Feedback

Curious about our installation quality in actual Mississauga residential and commercial spaces? Browse through our installation showcase to verify installation integrity, joint consistency, and surface preparation. In our portfolio showcases, you'll observe ANSI A108-compliant installations, exact tile measurements, TCNA-compliant lippage management, and EJ171-standard movement joints. We detail adhesive choices, notch dimensions, coverage percentages, and expansion allowances for high-use and wet environments.

You can validate outcomes through client feedback associated with specific sites, tile installations, and service scopes. We showcase before-and-after documentation, close-up photos of precise cuts, waterproofing specifications, and drying periods. Filter projects by material selection (porcelain, stone, mosaic), layout design (herringbone, stack, offset), and environment (bath, kitchen, commercial). These documented records enable you to measure precision, timeline adherence, and measurable results on similar projects.

Maintenance, Care, and Lasting Performance

Protect finish quality with regular cleaning protocols that comply with manufacturer pH requirements and ASTM C1028/C1026 compatibility. Make sure to inspect grout joints for minor fractures, eliminate biofilm, and reapply penetrating or topical sealants according to ANSI A118/A136.1 intervals. Maintain records of maintenance cycles and retain SDS for authorized cleaners to guarantee long-term performance and warranty compliance.

Standard Cleaning Practices

Consistent maintenance preserves tile beauty and durability by eliminating damaging debris, regulating moisture, and avoiding chemical deterioration. Carry out weekly vacuuming using a soft-bristle attachment or hard-floor setting to remove particles that can produce micro-scratches. Continue with microfiber mopping using a balanced pH cleaner prepared following manufacturer specifications; stay away from strong acid or base products that harm glazes and finishes. Use a two-bucket method to minimize soil redistribution and refresh the solution when clearly contaminated. Quickly handle spills to reduce staining and safety issues. For textured or matte tiles, use a nylon scrub pad with minimal pressure to remove embedded soil. Wash completely with clean water to remove detergent traces get more info that collect dirt. Wipe the surface with lint-free towels to decrease moisture accumulation and stop biofilm growth.

Grout and Sealant Care

Once establishing surface cleaning protocols, concentrate on sealant systems and grout joints, which primarily affect lasting performance. Assess grout lines for cracks, pinholes, and mineral deposits; note problem spots and humidity conditions. Utilize non-acidic cleaners and a soft-bristle brush to eliminate biofilm without compromising polymer binders. Treat porous grout according to recommended schedules, verifying ASTM C1368 water repellency. Select sustainable sealants with low VOCs and validate EC1 or GREENGUARD certification.

Review and analyze expansion joints along boundaries and meeting points; swap out deteriorated silicone with professional-grade ASTM C920 compounds. For addressing discoloration, utilize oxygen-based cleaners; refrain from applying acids to cement-based grout. Use these color matching methods: develop sample patches in actual project conditions and validate against samples in wet and dry states. Control humidity environment to ensure stable adhesion and hardening.

Common Inquiries

What Options Do You Have for Eco-Friendly and Low-VOC Adhesives and Grouts?

Indeed. There are low VOC adhesives and recycled content grout that satisfy GREENGUARD Gold or SCAQMD Rule 1168 limits. Our team uses polymer-modified, water-based formulations with VOC content under 50 g/L, and grout materials containing post-consumer recycled aggregates. You'll receive SDS and VOC certificates for every product. Furthermore, we follow ANSI A118 performance standards, perform mockups, validate cure times, and maintain proper ventilation to reduce emissions during installation and occupancy.

Do You Offer Locally Manufactured or Canadian Tiles Upon Request?

Absolutely, we can source locally made or Canadian tiles. Fortunately, your schedule matches our supply chain timeline, so we'll specify Canadian artisans and local manufacturers, confirm origin, and ensure CSA/ISO-compliant production. We'll gather production details, traction specifications (DCOF), VOC declarations, and freeze-thaw compatibility where applicable. We'll supply product documentation, samples, and delivery projections. We handle logistics, ensure precision for rectified edges, and match grout-joint tolerances to TCNA/ANSI installation standards.

Which Warranties Include Materials and Installation?

You're safeguarded by a Manufacturer warranty on tiles and setting materials per product specifications, and a written Workmanship guarantee on installation. You'll receive documented terms outlining duration (typically 10-25 years for materials; 2-5 years for labor), scope, and exclusions. Protection covers tile defects, adhesion problems, and labor per ANSI A108/A118 and TCNA guidelines. We register products, provide proof of compliance, and address issues through repair or replacement subject to environmental factors and upkeep.

What's Your Process for Handling Unforeseen Construction Challenges Identified During Construction?

We pause work, document our findings, and update you on the scope, building code requirements, and cost implications. For hidden damage, we conduct necessary invasive investigations. We provide a detailed written change order specifying repairs, required materials, and revised schedule. We collaborate with structural experts for structural integrity concerns, ensure Ontario Building Code compliance, and coordinate regulatory inspections. We provide daily status reports, complete with visual documentation and sign-offs. Construction resumes following authorization, preserving structural soundness and warranty protection.

Do You Coordinate With Other Trades for Complete Renovations?

We expertly handle electrical and plumbing scheduling with careful planning. We focus on detailed coordination and ongoing dialogue to eliminate interference. You get a detailed plan, certified plans, and regulatory-aligned scheduling. We execute preliminary site reviews, define fixture placements, confirm power calculations, and lock in component details. We organize timeline projections, system shutoffs, and inspection scheduling to meet CSA/ESA standards. You validate major milestones, and we track every change. This comprehensive approach reduces downtime, protects guarantees, and achieves reliable outcomes.

Summary

When you enter, you step onto a masterfully installed floor-tiles positioned with precision, with consistent grout lines, corners sharp. Moisture protection secures wet zones, protective coatings ensure longevity, and movement joints eliminate stress cracks. Transparent estimates, organized workflow, and punctual deliverables ensure project efficiency. We showcase a gallery of local installations and verified reviews validating professional craftsmanship. With appropriate maintenance practices-neutral cleaning solutions, regular sealer maintenance-you preserve surface quality and performance, ensuring your Mississauga spaces stay flawless, lasting, and attractive.